To download a PDF detailing this capability, click the following link: Fathom 4 Capability – Finite Element Analysis

The Fathom 4 FEA Team is able to perform simulations based on parameters set forth by the client’s specified standard (for example: MIL-STD 810G or 901D). Some of the practical applications include:

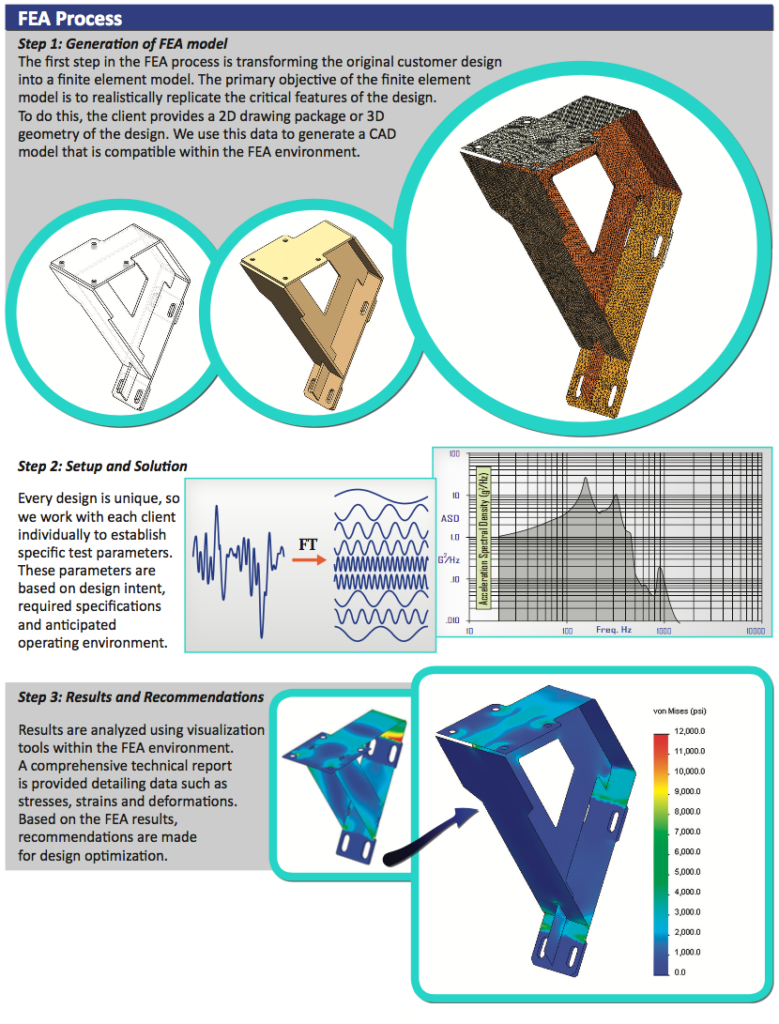

FEA allows for a detailed visualization of where structures bend or deform, and indicates the distribution of stresses and displacements. In addition, FEA is capable of a wide range of simulation options controlling the complexity of both modeling and analysis of any design.

Fathom 4 FEA Team

Our FEA team consists of multiple degreed mechanical engineers and full-time drafters dedicated to providing superior FEA services. Each of our engineers is experienced in the fields of part creation, finite element analysis and product performance. Every team member evaluates and provides input into each new FEA project in order to guarantee precise, thorough and detailed solutions.

Cost and Time Saving Benefits of FEA

Since FEA is a computer based tool we are able to complete

the entire process remotely – absolutely no travel involved! Additionally, FEA enables multiple test scenarios to be completed before fabricating a single part. This translates to considerable fabrication cost savings and a significantly reduced turnaround time between concept and production. FEA is an extremely cost effective tool to assist in the design and development of a multitude of structures. The many benefits of utilizing FEA to simulate complex problems include: