To download a PDF detailing this capability, click the following link: Fathom 4 Capability – Continuous Process Improvement

Fathom 4 can help your operation save production and labor costs with ease. The Fathom 4 Continuous Process Improvement (CPI) team combines unique backgrounds, varying viewpoints, and valuable skills sets to bring an educated and efficient approach to:

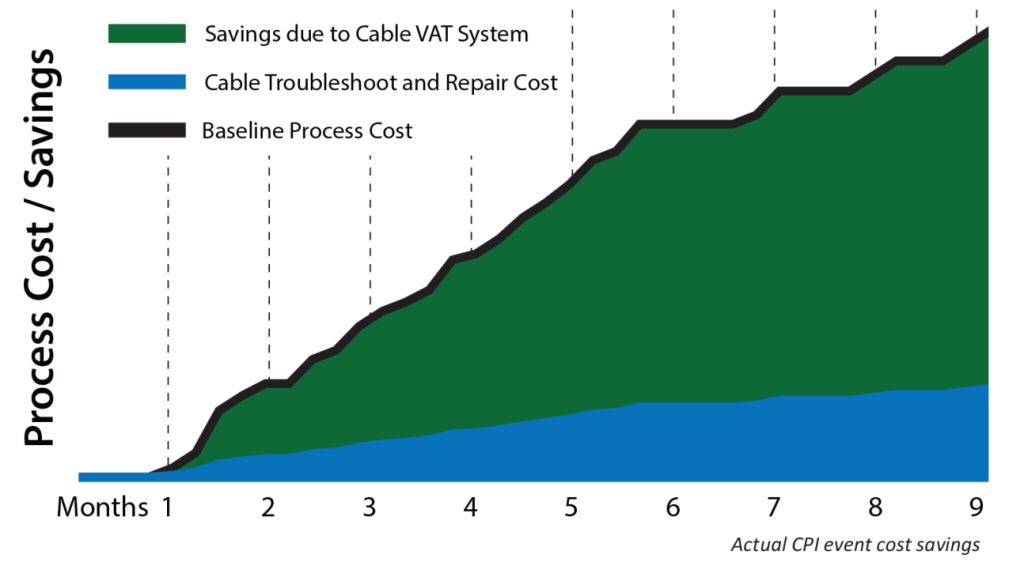

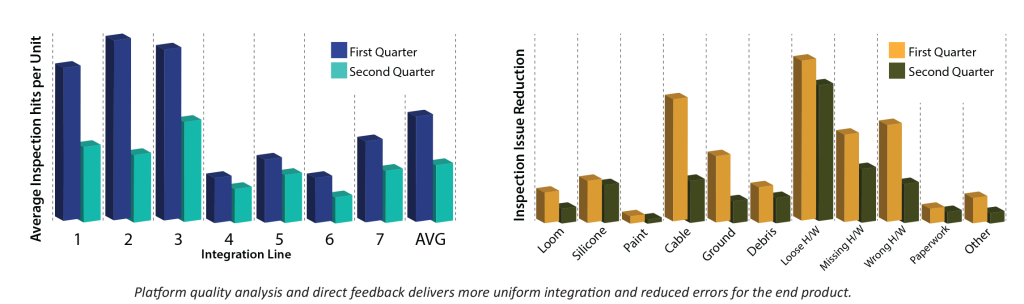

Fathom 4 has an established quality and performance management system that has been successful for various engineering, full rate systems integration, and logistics/supply projects. We have developed an internal team that conducts focused quality and performance management improvement initiatives, emphasizing low cost and minimal intrusion to the existing work force.

Our small team uses data collection processes that are web-based and automated to decrease the workload on the actual workers — maximizing the return on your investment.

Process Improvement Framework

The CPI team structures our framework around the Lean Six Sigma methodology of Define, Measure, Analyze, Improve, and Control (DMAIC). These five phases enable us to identify waste within a process, establish a process baseline, determine correlations between process components, develop more efficient solutions, train personnel in new procedures, and gain feedback from personnel to ensure lasting success.

Data Collection and Analysis

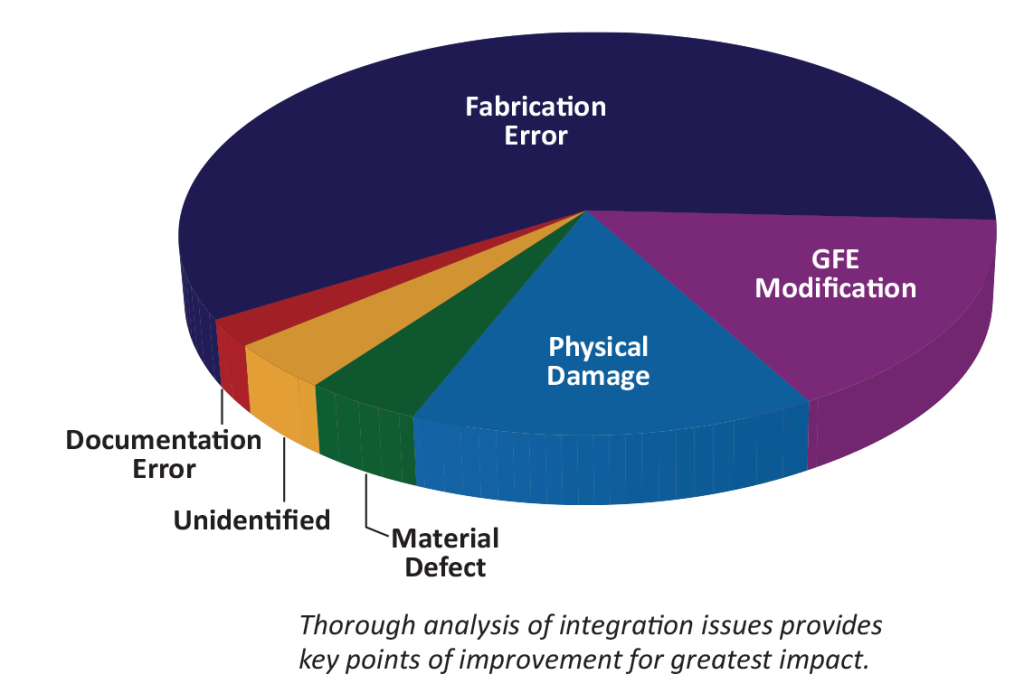

The Fathom 4 CPI team has extensive knowledge and expertise in analyzing the various types of raw data gathered from process improvement events. The team collects metrics that add to the overall depth of the analysis through the following methods:

The team employs the documentation philosophy that data recording should be as paperless and automated as possible. This allows for:

The raw data is then consolidated, interpreted, and evaluated to set attainable goals for the process. Results and solutions are tailored to meet the customer’s specific needs. The CPI team is skilled in presenting solutions to any audience, including management teams and a highly technical workforce.